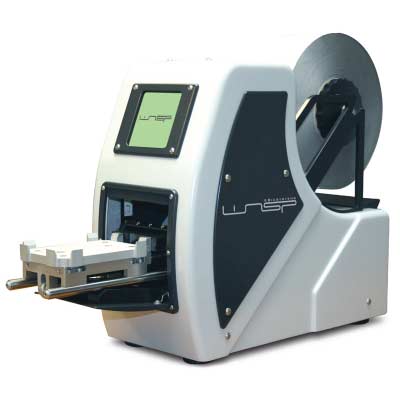

Plate Sealer - eSeal

kbiosystems 4th Generation fully electrically operated sealer offers automation laboratories require for a reliable, consistent plate and tube closing. This new electric sealer series is ground breaking for a market used to noisy pneumatically operated instrumentation.

The eSeal unit is an automated heat applied micro plate and tube rack sealer. The unit uses a roll of surface modified aluminium or plastic film approx. 78mm wide and 600m long, the roll is positioned to the rear of the sealing section via a removable stand, using a total inline method the film is pulled through the main unit, cut to between 115mm and 128mm in length and then applied to the plate top surface to create the seal between plate and film.

Offering complete versatility, the eSeal will work with a wide range of plates, tube racks and custom applications shallow and deep well formats, and custom mouldings.

Our latest range of seals support polystyrene, polypropylene and CoC & CoP plate formats with a range of film substrates please contact us for further details.

Constant time and pressure lead the way in sealing techniques, Kbiosystems developed the first fully automated production sealers way back in 1994 and still are considered the premier application specialist amongst users and integrators alike.

Foil roll to roll changing is a simple hand loading operation, no loading tools are required. Foil length can easily be changed within the control software and by using a force measurement system we can determine exact seal distances and pressures that have been validated in other systems to 13485 and UL standards.

Constant film control means that both normal and gas breathable films can be handled with no system set up changes.

Technical Specifications

- 4th Generation of Kbiosystems plate sealers

- All electric operation removes the risk of cross contamination inherent in compressed air powered sealers. No need for expensive compressed air supply

- Intuitive touchscreen user interface

- Variable foil length 115mm -128mm (set by touchscreen or user comm interface)

- Closed loop Seal force monitoring and control system, use of force sensors allows dynamic feedback during entire sealing process to ensure homogenous sealing

- Sealing force tolerance allows the force applied to be defined within the software

- Closed loop controlled sealing temperature

- Tool Free Foil loading

- Gas permeable films can be processed

- Automatically compensates for plate heights

- Integrator friendly design

- User settable Variable seal time and pressures via screen or comm

- Simple set up

- Quieter than conventional pneumatically driven unit

- Quick change maintenance modules for fast service response

KBiosystems Brochure 2019 PDF 3.6Mb

Similar Products

Wasp

Wasp

eFly 2

eFly 2

Cap-to-Mat

Cap-to-Mat

KAPS 500 Adhesive Sealer

KAPS 500 Adhesive Sealer