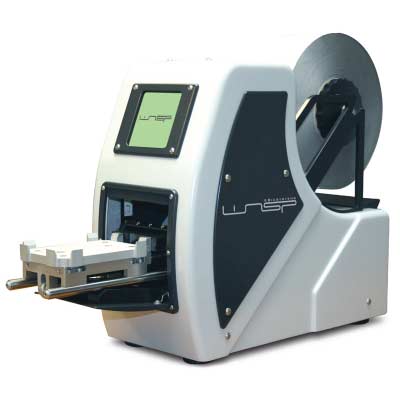

Plate Sealer - The Wasp2

The Wasp unit is an automated heat applied micro plate and tube rack sealer. The unit uses a roll of surface modified aluminium or plastic film approx. 78mm wide and 610m long, the roll is positioned to the rear of the sealing section via a removable stand, using a total inline method the film is pulled through the main unit, cut to between 125mm and 130mm in length and then applied to the plate top surface to create the seal between plate and film.

Offering complete versatility, the sealer Series will work with a wide range of plates, tube racks and custom applications shallow and deep well formats, and custom mouldings.

Our latest range of seals support polystyrene, polypropylene and CoC & CoP plate formats with a range of film substrates please contact us for further details.

Constant time and pressure lead the way in sealing techniques, KBiosystems developed the first fully automated production sealers way back in 1994 and still are considered the premier application specialist amongst users and integrators alike.

System operation is designed to efficiently apply a heat activated sealing film to a micro well plate or tube rack top surface. By pulling and maintaining control of a reel of film cutting to the desired length and by means of heat and time based variables apply the film to achieve the seal. The unit is both pneumatically and electrically operated and hence will require both supplies to be readily available.

Gas Purge option allows the user to lay a heavy gas coating to the well surface prior to sealing, this will then once sealed offer a protective barrier to the air void often left between sample and seal, with the gas laid prior to sealing an oxygen reduce or virtually oxygen free space environment can be achieved.

Technical Specifications

- Throughput: 6 plates per minute

- Operator Friendly: Easy to program and operator and integrator friendly

- Versatile: Able to use multiple plastic ware manufactures plates across applications.

- Reliable: Engineered with robustness in mind

- Electric: The unit can handle both 110 / 220 VAC supplies but must be rated to min 6Amp

- Pneumatic: The unit requires a supply rated to min 5.5bar max 6.5bar 50 litres per min.

- Weight: Approx. 12 kgs

- Dimensions: 630mm L x 192mm W x 435mm H (Inc. film roll)

- Comms lead: 3m RS232 (3 wire 2,3 and 5 connection non twisted)

- Comms driver: Supplied with KBiosystems communication protocol

- Shuttle extension: Offers greater access to plate nest extends + 34mm

- Gas Perm seal: Requires high LPM air supply rated to a min of 140LPM at 5.5bar

- Gas Purge: Requires Heavy gas supply 6mm pipe with 0 to 10 PSI control, additional gas safe monitoring will be needed or suitable fume hood.

We offer a full complementary range of foils to suit our sealers, and those of other manufacturers including, peel seals, pierceable seals, thermal bond seals, gas permeable seals and more

Wasp2 Product Overview PDF 1.2Mb

Replacing Plate Shuttle on a WASP Plate Sealer PDF 165Kb

Wasp cutter air fitting access PDF 84Kb

Wasp Base Access Procedure PDF 162Kb

Colour display screen replacement PDF 70Kb

Outer cover removal procedure PDF 105Kb

Wasp Cutter adjustment PDF 84Kb

WASP Extended Shuttle Fitting PDF 416Kb

Extended shuttle speed restrictor kit PDF 169Kb

Wasp Foil Vacuum Switch adjustment PDF 81Kb

Wasp Front Foil Gripper adjustment PDF 90Kb

Heater block removal sequence PDF 209Kb

LOW AIR sensor PDF 90Kb

Wasp Parts Diagram PDF 538Kb

Wasp Rear Foil Gripper PDF 175Kb

Wasp Screen PDF 112Kb

Shuttle Cylinder sensors PDF 129Kb

Wasp Vacuum Cup Inspection PDF 92Kb

Similar Products

Cap-to-Mat

Cap-to-Mat

KAPS 500 Adhesive Sealer

KAPS 500 Adhesive Sealer

Firefly Heat Sealer

Firefly Heat Sealer

Chameleon XT

Chameleon XT