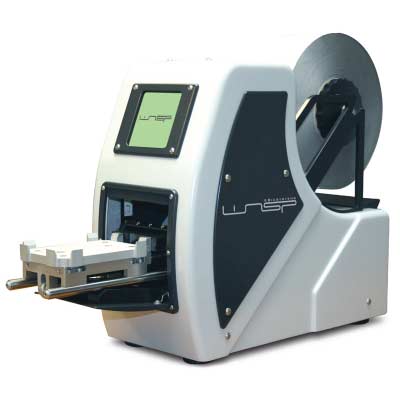

FireFly - Heat Sealer and Laser Cutting Platform

The FireFly uses a fiber laser to generate a beam using a core laser source and amplify it in specially designed glass fibers, supplied with energy via pump diodes. With a wavelength of 1.064 micrometres, the beam produces an extremely small focal diameter, making the intensity up to 100 times greater than conventional CO2 lasers.

The FireFly is highly suited for metal cutting, or marking metal or light range absorbent materials for high-contrast plastic marking or cutting. The unit is maintenance-free, and promises a long service life of at least 25,000 laser hours.

Technical Specifications

- Desktop automated heat sealing and laser cutting system

- Designed for SBS format tube racks

- Custom applications and cut profiles upon request

- Plates/tube racks can be pre-scored leaving minimal seal thickness to reduce tip/probe piercing pressures

- Tubes can be individualised to allow random access in any format, also allowing seal or cut-only processing

- Plate/tube rack heights with no adjustment from 7 to 48mm high

- Seal pierce operational compliant, allows plates to be stored fully sealed then pre-pierced to reduce tip damage

- Auto plate/rack present sensing

- Foil present sensing

- Low air sensing

- Inbuilt touch panel, PC-based, GUI controlled

- Stacker compatible with KBiosystems Scorpion stacker for increased throughput

- Integrator friendly

- Plate density independent, 96, 384, 1536, 3456 and higher

- Plates can be resealed and then re-pierced multiple times

- Minimal heat transfer from laser

- Uses latest Fibre laser technology for long process life

- Extraction port if require fitted to system top

- Length, Shuttle in: 640mm

- Length, Shuttle out: 830mm

- Shuttle Height: 200mm

- Width: 455mm

- Height: 730mm inc. extraction port

- Power requirement: 110/220 vac

- Main air supply: 5.5bar (85psi) at 70LPM

- System weight: 90kgs

KBiosystems Brochure 2019 PDF 3.6Mb

Similar Products

Wasp

Wasp

Cap-to-Mat

Cap-to-Mat

KAPS 500 Adhesive Sealer

KAPS 500 Adhesive Sealer

Chameleon XT

Chameleon XT